Neglecting regular maintenance can lead to a range of problems that can disrupt your operations. In this article, we will discuss the common problems of a poorly-maintained lift station and how they can impact you.

From pump failure to clogged pipes and unpleasant odors, these issues can be costly and inconvenient. As a lift station owner, it is crucial to be aware of these problems and take proactive steps to prevent them.

By understanding the importance of regular maintenance, you can ensure the smooth operation of your lift station and avoid costly repairs in the future. Don’t let a poorly-maintained lift station disrupt your operations – take action now and safeguard your investment.

Excessive Pump Wear and Tear

One common problem of a poorly-maintained lift station is the excessive wear and tear on the pumps. When lift stations aren’t properly maintained, the pumps are subjected to increased stress and strain. This can lead to a variety of issues, such as decreased pump efficiency, increased energy consumption, and ultimately, pump failure.

Without regular maintenance, debris can accumulate in the pump impeller and cause clogs, leading to pump overload and increased wear. Additionally, lack of lubrication and inadequate alignment of the pump components can further contribute to excessive wear and tear.

It’s crucial to prioritize regular maintenance and inspection of lift station pumps to ensure optimal performance and to prevent costly repairs or replacements. By taking proactive measures to address wear and tear, you can extend the lifespan of your pumps and maintain the efficiency of your lift station.

Electrical Malfunctions and Power Outages

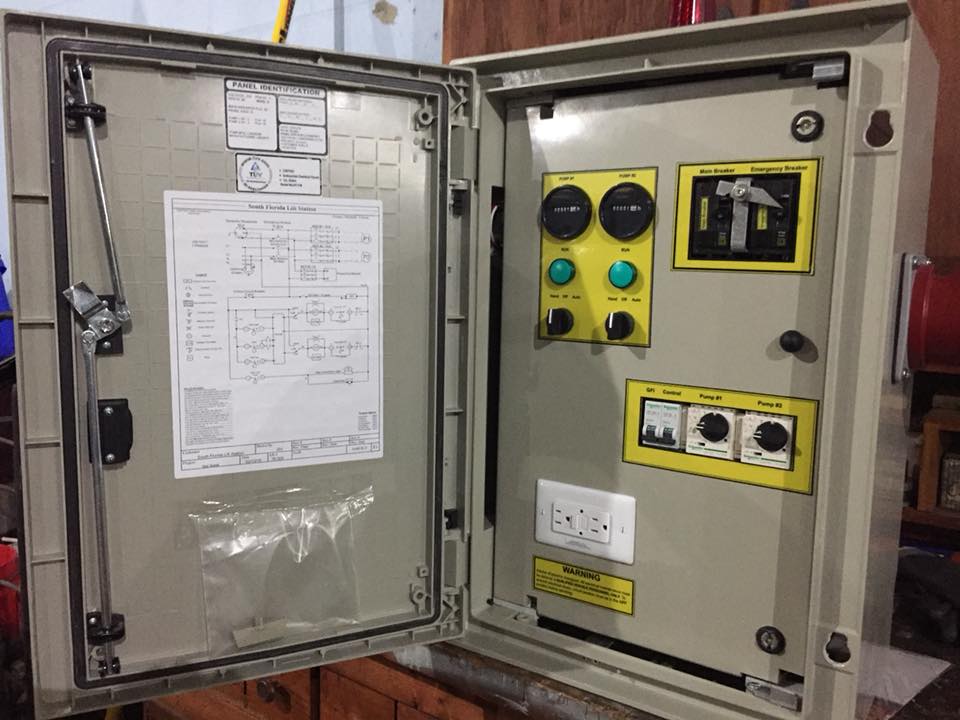

To address another common problem of a poorly-maintained lift station, let’s delve into the issue of electrical malfunctions and power outages. These issues can cause significant disruptions in the operation of your lift station and can lead to costly repairs and downtime.

Electrical malfunctions, such as faulty wiring or damaged components, can result in the pump not starting or operating at a reduced capacity. Power outages, on the other hand, completely halt the functioning of the lift station, leading to a backup of wastewater and potential environmental hazards.

Regular maintenance and inspections are crucial to identify and address any electrical issues before they escalate. It’s recommended to have a backup power source, such as a generator, to ensure uninterrupted operation during power outages.

Clogged or Blocked Pipes and Valves

Check for debris buildup in your pipes and valves to prevent clogs and blockages.

Over time, materials such as grease, sediment, and foreign objects can accumulate, obstructing the flow of wastewater in your lift station. These blockages can lead to decreased efficiency, increased energy consumption, and potential system failures.

Regular inspections and maintenance are crucial to identify and remove any obstructions in the pipes and valves. Clearing the debris promptly will help ensure the smooth operation of your lift station and prevent costly repairs.

Consider implementing a preventive maintenance plan that includes regular cleaning of the pipes and valves to minimize the risk of clogs and blockages. By taking proactive measures, you can maintain the optimal performance of your lift station and avoid unnecessary disruptions.

Corrosion and Rust Build-Up

When neglecting maintenance, you risk facing the problem of corrosion and rust build-up in your lift station.

Corrosion occurs when the metal components of your lift station come into contact with water or other corrosive substances. Over time, this can weaken the structural integrity of your lift station and lead to leaks or even complete failure.

Rust build-up, on the other hand, happens when the metal components are exposed to the oxygen in the air. This can cause the metal to deteriorate and become weak, compromising the efficiency and reliability of your lift station.

To prevent corrosion and rust build-up, regular maintenance is crucial. This includes inspecting and cleaning all metal components, applying protective coatings, and ensuring proper drainage to minimize contact with water.

Inefficient Pump Performance

If you have a poorly-maintained lift station, you may notice a significant decrease in pump performance. Inefficient pump performance can lead to various issues and negatively impact the overall operation of the lift station.

One common problem that arises from this is reduced flow capacity. When the pump isn’t functioning at its optimal level, it may struggle to move the required amount of water efficiently. This can lead to backups, clogs, and potential overflows.

Another issue is increased energy consumption. Inefficient pumps require more energy to operate, resulting in higher utility bills.

Additionally, poor pump performance can cause excessive wear and tear on the equipment, leading to premature failure and costly repairs.

To avoid these problems, regular maintenance and inspections are essential to ensure the pump is operating at its best.

Neglecting regular maintenance of your lift station can lead to a range of problems, including excessive pump wear and tear, electrical malfunctions, clogged pipes, and corrosion.

By taking proactive steps and implementing effective maintenance strategies, you can avoid these issues and ensure the smooth operation of your lift station.

Don’t let a poorly-maintained lift station disrupt your operations – prioritize regular maintenance to safeguard your investment and avoid costly repairs in the future.

Safeguard Your System with South Florida Lift Stations

Remember, neglecting maintenance not only leads to costly repairs but also poses risks to the environment and surrounding communities. With our expertise, we offer tailored solutions to keep your lift station operating at its best.

Don’t wait for issues to escalate; call today to learn more about how South Florida Lift Stations can enhance the performance and reliability of your lift station. Take the proactive step towards a seamlessly functioning system – your investment in maintenance today ensures a trouble-free tomorrow.