Welcome to

South Florida Lift Stations

With a new look in pumping solutions, South Florida Lift Stations Inc.

is moving forward as a company in a direction with two focuses.

Introduction

As a Veteran-Owned and Operated business led by a former United States Navy aviation machinist, we bring discipline, precision, and integrity to every job. We offer a wide selection of top-tier pumps from trusted brands like Homa, Myers, Zoeller, and Hydromatic, ensuring the right solution for your needs. Count on us for your residential, commercial, or municipal systems.

Liberty Pumps Distributor For SW Florida

24/7 Emergency Repair Services Available

We’re ready to respond day or night for fast, reliable emergency repairs. To South Florida Lift Stations Inc., every customer is our top priority. Contact us today!

Why Choose South Florida Lift Stations Inc.

SALES

We carry all major brands thus giving our customers different options when purchasing new parts. Our sales team will always give you expert and educated advice and can also help with specific case design.

SERVICE

Our service department is staffed with factory trained and certified technicians. This ensures you that your equipment is being properly serviced by the most knowledgeable and qualified personnel available.

MAINTENANCE

We recommend that all systems with pumps and motors are checked monthly to avoid any problems. The number of visits varies depending on the number of hours your system is operating.

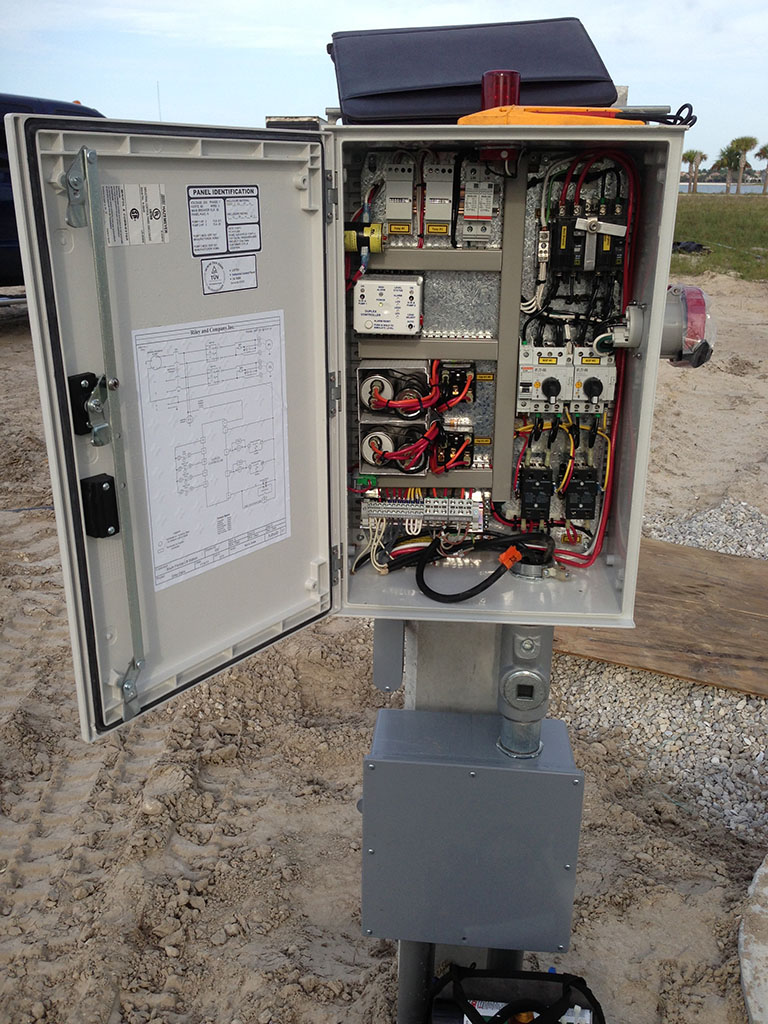

What Is A Lift Station

A lift station can be used in more than one application, as far as water transportation, sewage, wastewater and sludge. With specified gallon per minute and a total dynamic head pressure a station can deliver an excellent solution to all your pumping needs. A lift station is most commonly used in a fiberglass wet well or a concrete wet well, in some cases a fiberglass / concrete holding or dosing tanks.

Control panels for lift stations can be personally designed to meet the specifications for any job. In many applications a lift station can be a temporary or permanent route to providing a pumping solution. For example South Florida Lift Station Inc. uses H20 traffic bearing fiberglass basins and fiberglass reinforced valve boxes all hatch covers are constructed out of aluminum and all hardware is 304 stainless steel.

The pumps are designed to slide up and down on guide rail systems with a locking cantilever discharge base for easy and convenient installation and removal of pumps. Pumps come in all sorts of models as far as: Grinder Pumps, Non Glog Pumps, Sump Pumps and Sludge Pumps. Please contact us for you’re innovative pumping solution.

Our Service Areas

- Fort Myers

- Naples

- Punta Gorda

- Port Charlotte

- Englewood

- Marco Island

- Bonita Springs

- Cape Coral

- Arcadia

- Estero

Scan & Share Your Feedback!

We’d love to hear about your experience!

Simply scan the QR code and leave us a quick review.

Your feedback helps us improve and serve you better. Thank you for your support!

Contact Us Now!

Blog Posts

Safety Guidelines for Servicing Lift Stations

Before you even think about servicing a lift station, you should treat the area like a secret base and your equipment like a life raft. You prepare for the task at hand by dividing up responsibilities, learning about potential biohazards and slip hazards, and donning the appropriate personal protective equipment.

How to Neutralize Sewage Odors

Sewage odors seep in when conditions become anaerobic, much like a window left open to a stubborn odor. You can address these issues by increasing beneficial microbes that digest waste and using light-driven oxidation to break down volatile compounds. Real-time monitoring keeps everything in balance, reducing odors and improving health.

Lift Stations & Public Health: Why Proper Maintenance Matters

Lift stations keep wastewater moving, protect streets and homes from sewage backups, and reduce disease transmission from contaminated surfaces. When they run smoothly, they reduce storm-related overflows and increase community resilience. However, their performance is dependent on intelligent automation, regular maintenance, and clear emergency plans. You might believe that the